process

new reeded drawer pull | burnished light antique brass

We have added another member to the “Mayer” hardware family! ( family photos below ) To produce this pull, a professional

hand hammered | mod cabinet knobs

This gorgeous set of cabinet hardware involves a rather detailed process worth noting. Although it is time consuming, we make sure

ice box hardware | bright brass

Here is a neat shot of our traditional ice box hardware waiting to get lacquered. With the help of the lacquer,

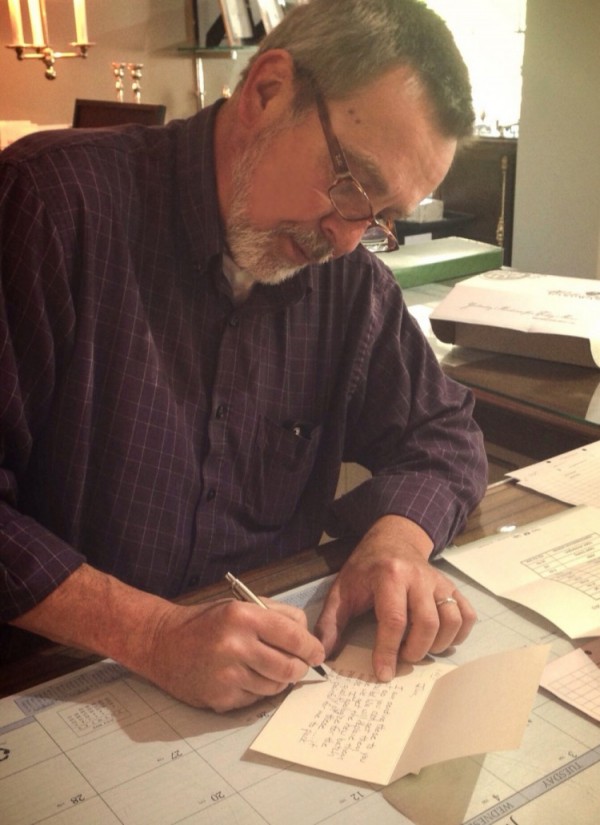

personal touch

Here is our General Manager, Ken, writing a letter to go along with a client’s hardware. We take pride in our

custom hardware step by step

This post is a bit different – and hopefully more educational as well. We recently made hardware that resides in the